Packet Sorting

Realtime Systems Project

The packet sorting project was my so-called “Scheinarbeit” for my realtime systems class in the fourth semester. At my university, in some classes you have to get a so-called “Schein” first through some kind of project before you are allowed to participate in the exam.

For the realtime system class, we built groups of two and could choose from many topics, and my teammate Marcel and I chose the packet sorting project.

The main target of this project was to program a conveyor belt to sort parcels according to the barcode on the parcels. As it is a university internal project, I can not show you the blueprints of the laboratory setup but let me explain it to you:

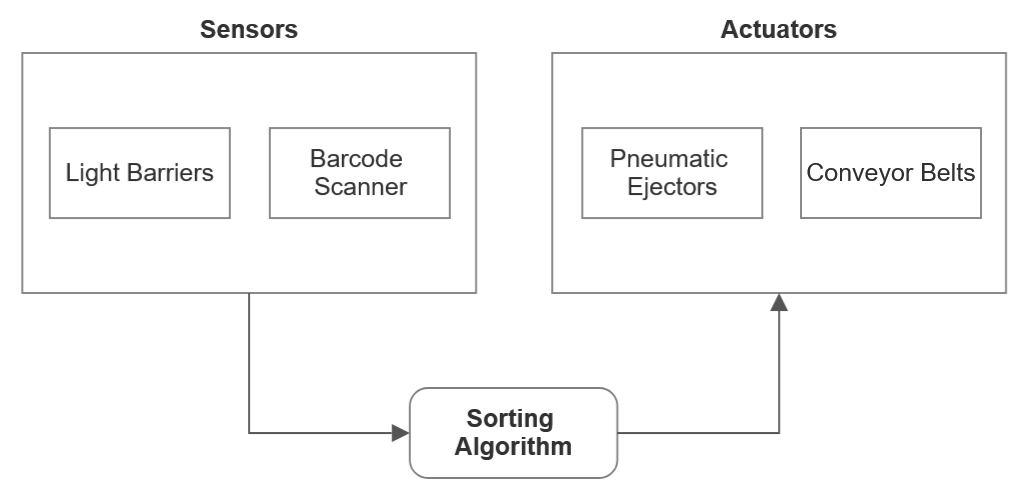

The already mentioned conveyor belt is separated into two sections that can be controlled separately, which will later be used to create equal spacing between the packages. Also, there is of course a barcode scanner to read the barcodes on the packages. To track the packages’ positions, there are 5 photoelectric barriers. And finally, for the sorting, there are three pneumatic ejection areas where a parcel can be pushed off the conveyor belt.

From a software point of view, we used RTAI, a realtime capable Linux system, and we used C as the programming language.

The challenging part was now to create enough distance between all the injected packages, scan their barcodes, check what the correct ejection point is, and then track the parcel with the light barriers until it can be ejected.

The following diagrams should explain our solution to this problem pretty well:

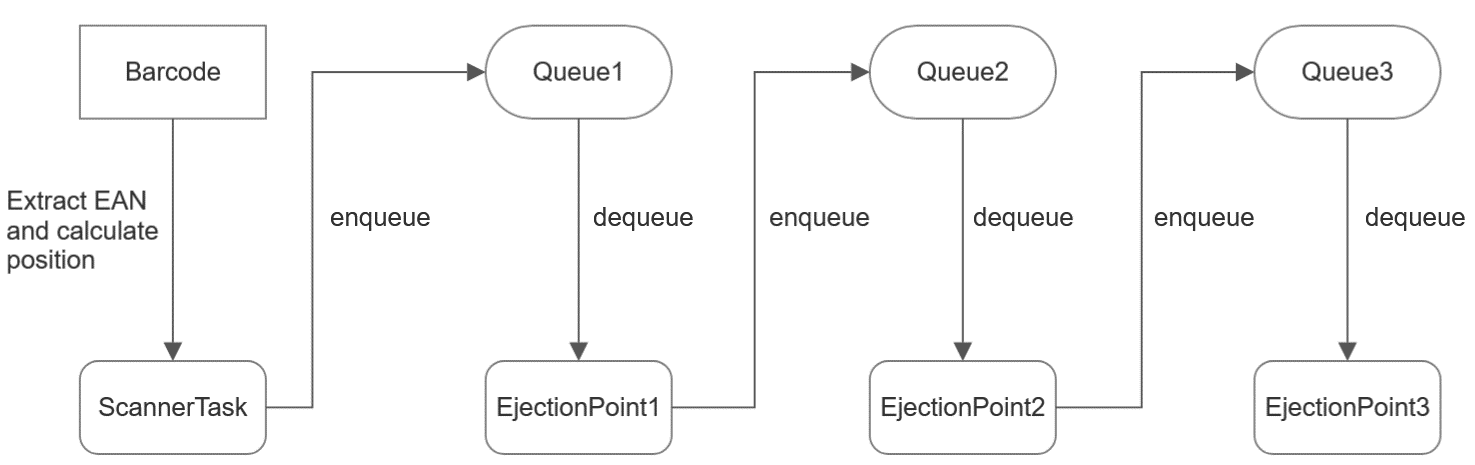

This diagram is maybe a little difficult to understand with so little context, so here’s how we explained the scanner system in our project report:

The purpose of the scanner system is to ensure the correct spacing of the parcels before letting them into the ejection area while also scanning the barcodes and calculating the correct position/tray to eject. The system recognizes a package when the first light barrier is interrupted, which leads to a stop of the first conveyor belt in front of the scanner. This ensures the correct spacing between the currently incoming package and the following package. When the package reaches the first light barrier, it is also in reach of the scanner, which automatically reads the barcode and sends the EAN to the scanner system via the USB interface. This incoming signal is handled by a completely separate script, which is not implemented during this project but is already supplied with the laboratory documentation. The purpose of the script is to read the incoming signal on the USB and put the EAN in the FIFO-queue. Once a new element enters the queue, the FIFO handler of the scanner system is triggered, which reads the EAN from the FIFO and calculates the ejection position of the EAN according to its last digit. Once the position is calculated, it is enqueued into the first queue, which is assigned to the first ejection area. Simultaneously, the package moves along the belt, as the conveyor belt is still activated. When it leaves the first light barrier again, the scanner system reactivates the barcode scanner for the next package, as it deactivates itself after each scan. Additionally, the conveyor belt in front of the scanner area is activated again as well to push the next parcel into the scanner area.

As the main part of the conveyor belt is always running and the distance between the packages is kept at a minimum, this solution also achieves maximum throughput.

For a deeper look into our approach please have a look into the source code.